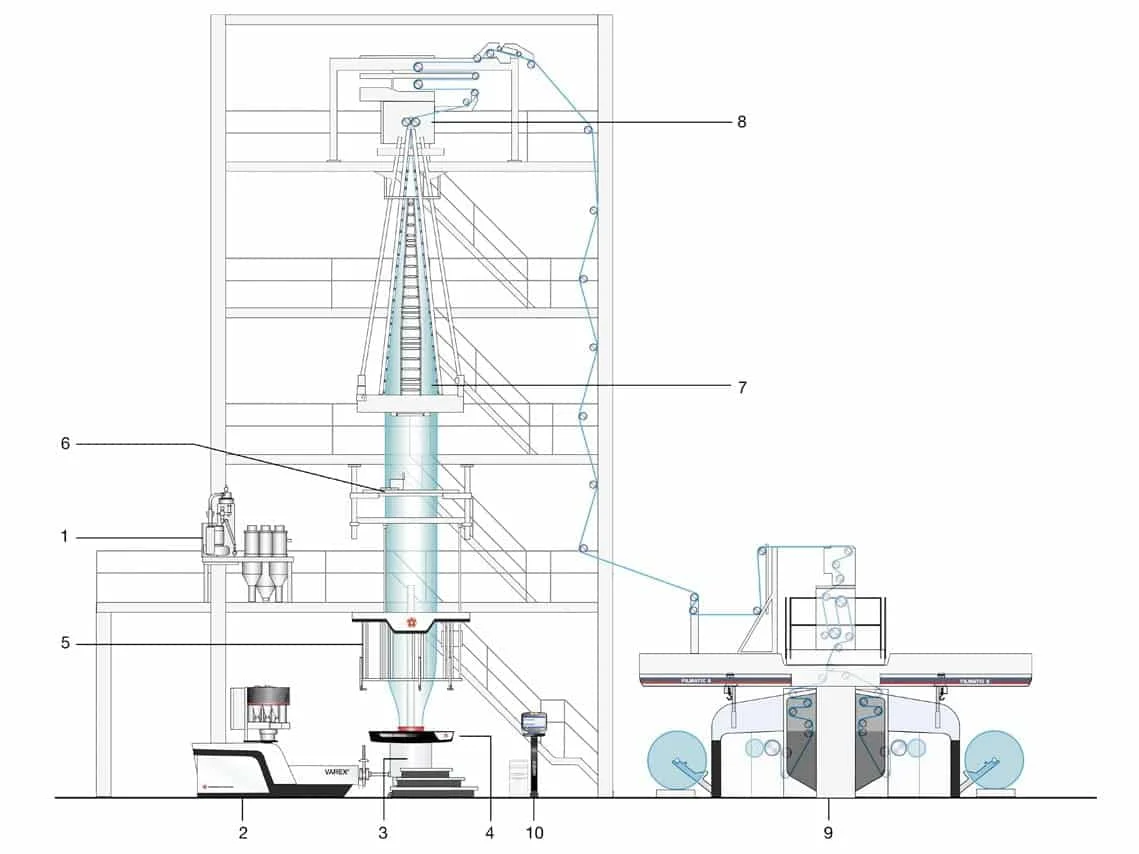

Process Info

What Are the Polyethylene Blow Film Types?

Polyethylene blow film come in different forms. It can be manufactured in different colors or be transparent. In addition, blown plastic film comes in different thicknesses. The thicker the virgin film, the stronger it is. The film gets thicker as the numbers of microns increase. The three most common types of polyethylene are:

1. Low-Density Polyethylene (LDPE)

This one is commonly used to manufacture plastic products like shopping bags. It is a highly flexible material with unique gloss properties.

2. High-Density Polyethylene (HDPE)

This type of plastic has a denser form, and the end-result is usually stiff plastic, thanks to its highly crystalline structure. It is commonly used to manufacture garbage bags, milk and laundry bags, shopping bags, sugar packing rolls.

Advantages of Using Polyethylene Film

Its many advantages are what makes a polyethylene film a preferred choice. The below listed advantages vouch for their dependability:

1. Assured Protection:

The first advantage of polyethylene film is to provide excellent protection. It is leakage-proof, and great for heat sealing; meaning that it can be wrapped around the product and secured with an airtight seal.

2. High Flexibility:

Low-Density Polyethylene (LDPE) is soft, puncture-resistant, highly transparent, and heat seal-able, making it the ideal choice for wrapping products, tubing, and packaging of auto parts. The slightly denser version of LDPE is used to manufacture packaging bags for sharper objects.

3. Highly Adaptable:

Polyethylene can be tailored to suit different needs. It comes in different colors, clarities, and thicknesses and it is printable. It can best display the products, as well as keep them sheltered, if required. This PE trait makes it easier to advertise a product.

Also Check